The call came at 6:47 AM. Setup was supposed to start at 7:00. The venue coordinator’s voice had that particular tremor I’ve learned to recognize over fifteen years in this business—the sound of someone watching a carefully orchestrated plan collapse in real time.

“We have a problem,” she said. “The freight elevator is down.”

Three floors worth of exhibition booths, staging equipment, and audiovisual gear sat in our trucks outside. Two hundred exhibitors would arrive in less than six hours expecting their spaces ready. And the only way up was a passenger elevator with a weight limit that wouldn’t accommodate a determined house cat, let alone a modular booth system.

This wasn’t anyone’s fault, really. The venue had seemed perfect during the site visit three months earlier. Beautiful space, good loading access, plenty of power outlets. We’d checked all the usual boxes. But we never asked about elevator maintenance schedules or backup plans. Why would we? The elevators worked during our walkthrough.

That morning taught me something I wish I’d learned earlier: the things that destroy events aren’t the obvious challenges you plan for. They’re the invisible details lurking beneath the surface, waiting for the worst possible moment to announce themselves.

Let me share three site issues that almost never make it onto anyone’s pre-event checklist, but probably should be at the very top.

1. Floor Load Capacity: The Silent Saboteur

You’d think the ground beneath your feet is the one thing you don’t need to worry about. It’s literally holding up the building, after all. How could it possibly be an issue?

Here’s what nobody tells you until it’s too late: not all floors are created equal.

I learned this during an automotive showcase where the client wanted to display actual vehicles inside a historic convention center. Gorgeous space, high ceilings, dramatic architecture. During our planning meetings, we discussed power requirements, climate control, security protocols. The usual suspects. What we didn’t discuss was whether the second-floor ballroom could handle three tons of steel and chrome spread across ten display positions.

Spoiler: it couldn’t.

The venue’s floor was rated for standard event use—people, tables, staging, normal booth equipment. But concentrated weight loads from vehicles? That required engineering approval we didn’t have. We discovered this detail during a routine permit review, purely by accident, three weeks before the event. Moving everything to a ground-floor space meant redesigning the entire layout and renegotiating contracts with exhibitors who’d already begun planning their booth presence.

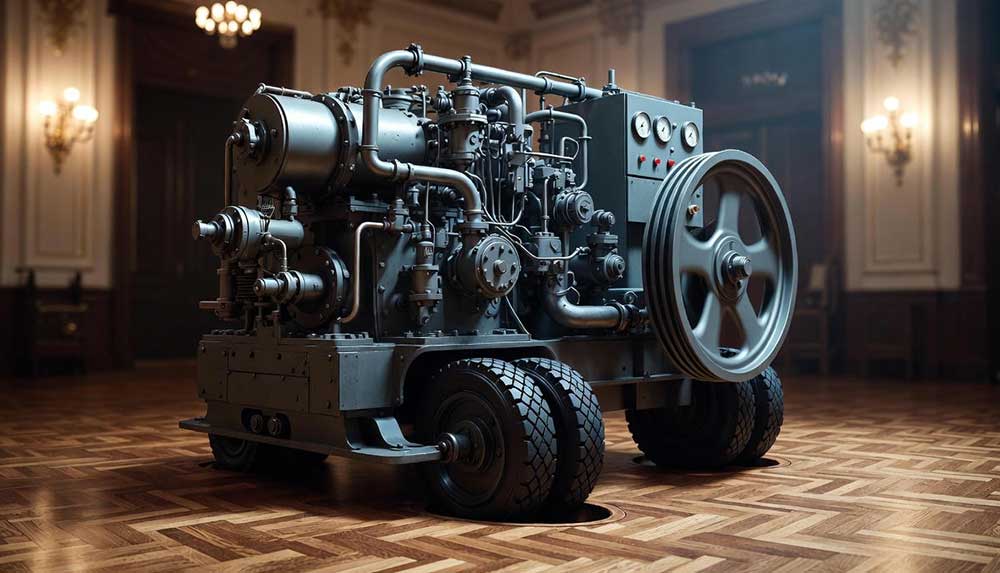

The nightmare scenario isn’t just heavy vehicles, though. It’s anything with concentrated load points. Multilevel booth structures. Water features. Large machinery displays. Even dense crowds gathering in unexpected patterns can exceed what older buildings were designed to handle.

The worst part? You can’t eyeball this problem. A floor that feels perfectly solid might have strict weight distribution requirements buried in engineering documents that nobody thinks to check until something goes wrong. And by then, you’re either scrambling for solutions or watching your event collapse—sometimes literally.

Ask about load capacity ratings before you even discuss floor plans. Get the numbers in writing. If you’re bringing anything heavier than standard pipe and drape, have that conversation early. Your future self will thank you.

2. Power Distribution: The Great Invisible Mystery

Everyone knows to ask about power. It’s event planning 101. “Do you have enough outlets?” seems like such a basic question that most people feel confident checking it off their list and moving on.

But here’s what that question doesn’t reveal: where the power actually comes from, how it travels through the building, and what happens when everyone tries to use it simultaneously.

I once contracted for a technology expo where every booth included multiple screens, computers, and demonstration equipment. The venue assured us they had “plenty of power”—and technically, they did. What they failed to mention was that the entire exhibition hall ran on three circuits, each serving roughly a third of the space.

Everything worked beautifully during setup when booths were testing equipment individually. Then opening day arrived. Nine o’clock hit. Every exhibitor powered up their displays at once. And two-thirds of the hall went dark.

The circuits couldn’t handle the simultaneous load. We spent the next forty-five minutes cycling through exhibitors, asking them to stagger their equipment startup times, while attendees wandered through a half-lit exhibition space wondering if they’d accidentally walked into a haunted house experience.

The venue wasn’t wrong about having sufficient total power capacity. But power distribution—how that electricity actually reaches different areas—was a completely different story. Old buildings often have electrical systems designed for their original purpose, retrofitted over decades with band-aid solutions that work fine until they don’t.

You need to ask different questions: What’s the amperage per circuit? How many outlets share each circuit? Where are the breaker boxes? What’s the protocol if something trips? Can we access panels ourselves or do we need venue electricians? And crucially: what’s the realistic sustained load, not just the theoretical maximum?

Some venues will look at you like you’ve asked for their banking passwords. Push anyway. Because discovering your power limitations after exhibitors have paid for booth space and traveled across the country is not a conversation anyone wants to have.

3. Access Timing: The Logistical Landmine

This one sounds almost too mundane to matter. When can you get into the space? Simple question, simple answer, move on with your life.

Except it’s never that simple.

Access timing isn’t just about unlock times and lock times. It’s about understanding the rhythm of a building’s entire ecosystem—and how your event fits into patterns you didn’t know existed.

I contracted for a corporate conference at a hotel that shared a loading dock with a restaurant, a catering operation, and three other event spaces. Our setup window looked perfect on paper: access at 6:00 AM for a 2:00 PM event start. Plenty of time.

What we didn’t know was that the restaurant received its daily delivery at 6:30 AM sharp. Every single day. Non-negotiable. Which meant our trucks had to clear the loading dock by 6:25 AM or wait until 7:15 AM when the delivery was finished.

Six trucks worth of booth materials don’t unload in twenty-five minutes. We ended up in a absurd choreography of moving half our equipment inside, pulling trucks out, waiting in a parking lot like we were in line at a fast-food drive-through, then circling back to finish. An eight-hour setup stretched to eleven hours because of a forty-five-minute window that nobody mentioned during planning.

But access timing issues go deeper than loading dock schedules. Union requirements might mean you can only work during specific hours or must use venue labor. Building security might restrict freight elevator access during business hours. Noise ordinances might prevent forklift operation before 8:00 AM. The ballroom next door might be hosting breakfast service until 10:00 AM, making your setup sound like an invasion force.

These restrictions often don’t appear on venue spec sheets or in initial conversations. They’re the kind of operational details that people assume you know, or that they don’t think to mention because they deal with them every day and forget they’re unusual.

You have to dig for this information deliberately. Ask about every other event happening in the building during your setup window. Ask about deliveries, maintenance schedules, and building operations that might intersect with your timeline. Ask what happens if you run over your access window—are there overtime fees, or do you simply lose access and have to resume later?

Map out the whole timeline with buffers built in, because the perfect schedule only exists in spreadsheets, never in real life.

The Invisible Checklist

That freight elevator disaster I mentioned at the beginning? We solved it eventually. Called in favors, rented equipment we didn’t budget for, reprioritized which booths absolutely had to be setup first, and somehow pulled together an exhibition floor that looked intentional rather than panic-induced. The event succeeded despite the chaos, and I don’t think most attendees ever knew how close we came to catastrophe.

But that’s the thing about these hidden site issues—they’re survivable when you catch them, devastating when you don’t, and completely preventable if you know to look.

The venues aren’t trying to deceive you. The challenges just live in blind spots that nobody thinks to illuminate until experience forces you to carry a flashlight everywhere you go.

So consider this your flashlight.

Before your next event, ask about floor load capacity ratings and get engineering documents if needed. Dig into power distribution systems and circuit layouts, not just total electrical capacity. Map out every possible access conflict and timeline constraint, assuming Murphy’s Law will find the worst possible moment to activate.

Because somewhere right now, someone is planning an event at a venue that seems absolutely perfect. And their phone is going to ring at 6:47 AM on setup day with a problem they never saw coming.

Don’t let that be you.